CDS-6000 pyrolyser range

CDS has launched a 6th generation of analytical pyrolysers that can be configured for standard and slow rate pyrolysis, pyrotomy, reactant gas pyrolysis (O2, H2, or gas of any choice), EGA studies, high pressure pyrolysis with reactant gas and elevated pressure through to steam pyrolysis. Other sampling options are available that makes the system much more than a polymer GC introduction system and can be considered as a thermal injection system for all matrices.

Analytical pyrolysis requires accurate control of pyrolysis temperature, pyrolysis time, and temperature ramp rate, the Model 6000 analytical pyrolysis system series provide control of all three parameters. Analytical runs may be programmed up to ten steps per sample from ambient to 1400°C with automatic control of the on-line valve, interface temperature, and GC ready/start for each step. The unique interfacing design permits a direct pyrolysis path to the GC inlet or rapid sample heating and transfer to the trap without interrupting the pneumatics of the GC. The transfer line can be co-installed with a GC liquid autosampler and can be removed in under 15 seconds if required.

Analytical pyrolysis requires accurate control of pyrolysis temperature, pyrolysis time, and temperature ramp rate, the Model 6000 analytical pyrolysis system series provide control of all three parameters. Analytical runs may be programmed up to ten steps per sample from ambient to 1400°C with automatic control of the on-line valve, interface temperature, and GC ready/start for each step. The unique interfacing design permits a direct pyrolysis path to the GC inlet or rapid sample heating and transfer to the trap without interrupting the pneumatics of the GC. The transfer line can be co-installed with a GC liquid autosampler and can be removed in under 15 seconds if required.

CDS pyrolysers employ resistively heated filaments ensuring there are no secondary pyrolysis fragments or condensation loss of high boiling point compounds. The systems can be installed quickly onto any GC/GCMS with control either by the built-in touch screen or PC software that is pre-programmed with a library of pyrolysis and thermal desorption methods.

CDS pyrolysers employ resistively heated filaments ensuring there are no secondary pyrolysis fragments or condensation loss of high boiling point compounds. The systems can be installed quickly onto any GC/GCMS with control either by the built-in touch screen or PC software that is pre-programmed with a library of pyrolysis and thermal desorption methods.

Features

- Install onto any commercially available gas chromatograph/GCMS/FTIR

- Programmable pyrolysis to 1400ºC in 1ºC increments with heating rates programmable from 0.01ºC/min to 20,000ºC/sec, and pyrolysis time programmable from 0.01sec to 999.99min

- Quick-connect transfer line to easily restore GC to original configuration

- Reactant gas, high pressure, catalyst, and steam options

- Trapping option for headspace and bulk headspace studies, now with test tube option

- Dry function for solvent evaporation prior to analysis for liquid samples

- Analysis of solids, powders, and liquids with choice of sample boats or tubes for easy sample preparation

- Two filament type option, ribbon or coil for easy analysis of solids, powders and liquids

- Automated leak check capabilities plus extensive troubleshooting down to component level

- Preprogrammed pyrolysis and thermal desorption method libraries

Sample introduction – new one-shot autoinjector

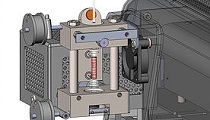

Sample probes are available in a variety of designs and sizes including a flat ribbon probe where the sample is placed directly on the platinum for pyrotomy studies, and a coil probe where solid and liquid samples are placed into quartz tubes before inserting into the platinum filament.

Sample probes are available in a variety of designs and sizes including a flat ribbon probe where the sample is placed directly on the platinum for pyrotomy studies, and a coil probe where solid and liquid samples are placed into quartz tubes before inserting into the platinum filament.

For the 6200 a unique one-shot autoinjector is included that consists of a ‘Drop in Sample Chamber’ (DISC) that eliminates the need to insert the sample tube into the coil probe. The DISC option is ideal for laboratories analysing a small number of samples or to reduce manual handling.

For the 6200 a unique one-shot autoinjector is included that consists of a ‘Drop in Sample Chamber’ (DISC) that eliminates the need to insert the sample tube into the coil probe. The DISC option is ideal for laboratories analysing a small number of samples or to reduce manual handling.

The 6000 series is available in two versions, the 6150 where pyrolysis takes place in the GC carrier gas, and the 6200 that can be fitted with a number of different options for flexibility e.g. reactant gases.

| Model | 6150 | 6200 |

|---|---|---|

| Pyrotomy (pulse) pyrolysis | Y | Y |

| Programmed pyrolysis | Y | Y |

| Evolved gas analysis (EGA) | Y | Y |

| Auto multi-step pyrolysis with sample off line between analyses | Y | Y |

| Interface to GC | Transfer Line | Transfer Line |

| Vent free adaptor for no-vent GCMS column change | Y | Y |

| FTIR interface for in-beam thermal analysis | Y | Y |

| GCMS polymer and additive libraries compatible with NIST AMDIS | Y | Y |

| One-shot autosampler | Y | |

| Thermal desorption, headspace, and pyrolysis trapping | Y | |

| Reactant gas analysis in air, O2, H2, or gas of any choice | Y | |

| Catalyst option with stand alone heated quartz tubular reactor | Y | |

| UV light module for UV irradiation of sample with xenon light | Y | |

| Steam option for hydrolysis reaction studies | Y | |

| Dynamic headspace vessel for bulk samples | Y | |

| Mass flow controller for purge and reactant gas flow control | Y | |

| Fixed gas analyser for measurement of CO, CO2, CH4, H2, H2O, C2H2, C2H4 | Y |

Sample focus trap

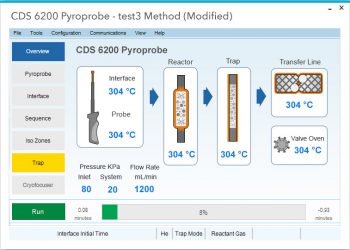

The 6200 system has a built-in low thermal mass analytical focus trap with active cooling. The trap includes a pre-desorb pre-heat function that seals both ends of the trap and pre-heats it prior to desorb to the GC. This process significantly improves the early eluting module compounds producing sharp peak shape resulting in improved peak resolution. A selection of trapping materials can be used depending on the analytes to be trapped.

The 6200 system has a built-in low thermal mass analytical focus trap with active cooling. The trap includes a pre-desorb pre-heat function that seals both ends of the trap and pre-heats it prior to desorb to the GC. This process significantly improves the early eluting module compounds producing sharp peak shape resulting in improved peak resolution. A selection of trapping materials can be used depending on the analytes to be trapped.

Mass flow controller

The optional electronic mass flow controller provides a programmable flow of reactant gas (O2, N2, He, CO2, and air) into the DISC pyrolysis chamber for kinetic studies. Programmed through the pyrolyser software, the mass flow controller provides an accurate flow rate of 0 – 100ml/min.

The optional electronic mass flow controller provides a programmable flow of reactant gas (O2, N2, He, CO2, and air) into the DISC pyrolysis chamber for kinetic studies. Programmed through the pyrolyser software, the mass flow controller provides an accurate flow rate of 0 – 100ml/min.

External catalyst reactor

The external tandem catalyst reactor option allows the study of high temperature catalyst reactions on a small scale in the laboratory before undergoing the time and expense of scaling up to a pilot reactor. Samples are initially pyrolysed in either the 6150 or 6200 pyrolyser and the pyrolysate is purged to the external reactor that contains a heated catalyst bed for secondary reaction. After the process is complete, the analytes are transferred to the GC at normal operating conditions. Any reactant gas can be used in the pyrolysis chamber including H2, O2, CH4 or CO with a catalyst bed of the users choice.

The external tandem catalyst reactor option allows the study of high temperature catalyst reactions on a small scale in the laboratory before undergoing the time and expense of scaling up to a pilot reactor. Samples are initially pyrolysed in either the 6150 or 6200 pyrolyser and the pyrolysate is purged to the external reactor that contains a heated catalyst bed for secondary reaction. After the process is complete, the analytes are transferred to the GC at normal operating conditions. Any reactant gas can be used in the pyrolysis chamber including H2, O2, CH4 or CO with a catalyst bed of the users choice.

Versatile accessories

The 6200 system is fitted with a Multi-Purpose Rail Mount (MPRM) to allow easy mounting of optional accessories, such as the Autosampler Module, Dynamic Headspace Module, Thermal Desorption Module, and Manual Probe. The MPRM provides assisted alignment when installing new modules.

The 6200 system is fitted with a Multi-Purpose Rail Mount (MPRM) to allow easy mounting of optional accessories, such as the Autosampler Module, Dynamic Headspace Module, Thermal Desorption Module, and Manual Probe. The MPRM provides assisted alignment when installing new modules.

System leak check

The 6200 system offers the ability to carry out a leak check of all sample lines. Controlled by the pyrolysis software, the leak check is conducted prior to an analysis that allows the user to conduct the pyrolysis studies with peace of mind. In addition, the self diagnosis capabilities aid in identifying possible leaks or possible blockages during routine preventative maintenance, servicing or if troubleshooting the system.

The 6200 system offers the ability to carry out a leak check of all sample lines. Controlled by the pyrolysis software, the leak check is conducted prior to an analysis that allows the user to conduct the pyrolysis studies with peace of mind. In addition, the self diagnosis capabilities aid in identifying possible leaks or possible blockages during routine preventative maintenance, servicing or if troubleshooting the system.

Superior resolution

The newly designed valve oven guarantees the sample path is evenly heated from the autosampler or DISC system to the integral trap and through to the transfer line to the GC. The design ensures that there are no ‘cold spots’ that would result in loss of pyrolysate through condensation and possible contamination. A heating temperature of 350 °C assures minimum carry over.

The newly designed valve oven guarantees the sample path is evenly heated from the autosampler or DISC system to the integral trap and through to the transfer line to the GC. The design ensures that there are no ‘cold spots’ that would result in loss of pyrolysate through condensation and possible contamination. A heating temperature of 350 °C assures minimum carry over.

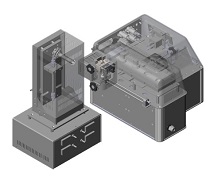

Easy maintenance

Both the 6150 and 6200 pyroprobes are designed with quick release panels that require minimum tools for access into the systems. The track pull-out design and drop down side panels enable faster servicing with easy diagnosis and quick exchange of parts to minimise instrument downtime. The design also enables easy and fast installation if either system is upgraded with some of the optional modules.

Both the 6150 and 6200 pyroprobes are designed with quick release panels that require minimum tools for access into the systems. The track pull-out design and drop down side panels enable faster servicing with easy diagnosis and quick exchange of parts to minimise instrument downtime. The design also enables easy and fast installation if either system is upgraded with some of the optional modules.

Software control

Control of the pyrolysis systems is either through PC software or via the built-in LCD screen. The built-in touch screen allows local start/stop of the pyrolysis GCMS system and displays current temperatures and pressures. The PC software resides alongside the GCMS operating software and is installed with 50 pre-programmed methods.

Control of the pyrolysis systems is either through PC software or via the built-in LCD screen. The built-in touch screen allows local start/stop of the pyrolysis GCMS system and displays current temperatures and pressures. The PC software resides alongside the GCMS operating software and is installed with 50 pre-programmed methods.

Libraries

With the vast array of polymers and additives, and the continual development of new ones, finding trace amounts in an unknown polymer sample is becoming increasingly difficult. CDS has developed several libraries for polymers, polymer additives, and even biofuel compounds. The libraries contain hundreds of spectra to make the most comprehensive set of libraries that will aid in making data interpretation easier than ever.

Polymer library

Most polymers are not included in standard GCMS search libraries as the whole polymer itself cannot be chromatographed. The Polymer Library consists of 500+ polymer standards where the individual spectra from a pyrolysis chromatographic run are averaged to produce one spectrum for that polymer. At the end of a sample run, the whole TIC is averaged and compared to the Polymer Library.

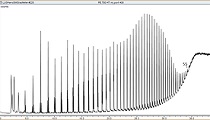

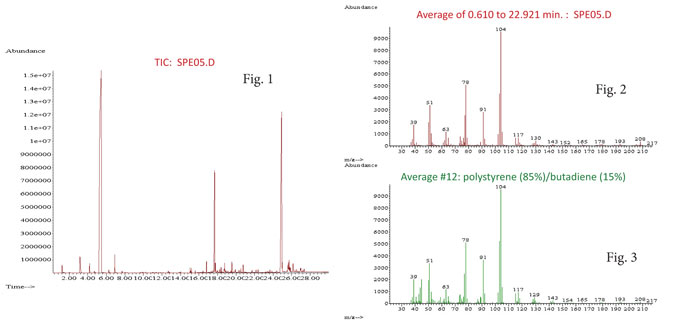

An example is a sample of clear plastic that when pyrolysed produced styrene monomer, dimer and trimer indicating polystyrene, which is a logical choice for this kind of material (Fig. 1.). When the pyrogram was averaged (Fig. 2) and searched using the polymer library, the best fit was for a copolymer of styrene and butadiene (Fig. 3) and not pure polystyrene. Closer investigation of the smaller peaks in the pyrogram did reveal the presence of butadiene oligomers, information that may have been missed by a visual inspection of the pyrogram.

Additives library

The number of polymer additives is growing constantly and are often difficult to identify as they are present at trace levels and sometimes not found in Wiley or NIST libraries. The Additive Library contains 500+ compounds and is used in conjunction with a deconvolution program such as AMDIS that assists in searching for user specified compounds in a complex pyrogram.

The polymer additives libraries are categorised under searchable subgroups such as:

- Additives

- Flame Retardants

- Plasticisers

- Stabilisers

- Antioxidants

- Lignocellulosics