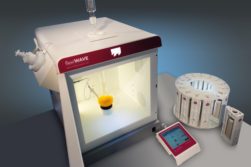

Milestone flexiWAVE microwave synthesis system

The Milestone flexiWAVE synthesis system overcomes the limitation of conventional microwave synthesis devices as it has a microwave cavity in excess of 70 litres in a single instrument platform that, in combination with specific accessories, allows the chemists to perform classic glassware and high pressure synthesis, as well as solid-phase reactions. The flexiWAVE is equipped with two 950 Watt magnetrons providing up to 1900 Watt making it the most powerful system available for organic and inorganic synthesis. An integral camera interfaced with the control terminal provides a video of the entire run and allows the chemist to monitor the progress of the chemical reaction whilst fully protected by the all-stainless steel door of the instrument.

Benefits

- Flexibility with three techniques in one instrument – classic glassware synthesis, high pressure synthesis, solid-phase reactions

- Improved yields with reactions completed in minutes instead of hours

- Lower by-products formation and sample contamination

- Microwave field homogeneity with fast and homogeneous heating of samples thanks to a rotating diffuser

Classic glassware synthesis

The Classic Glassware setup allows use of all commonly used laboratory glassware and provides the suitable apparatus for a full reaction optimisation for research or teaching purposes. It allows the chemists to perform synthetic reactions under reflux and any chemical reaction currently carried out with hot plates, heating mantles or oil baths that could be rapidly improved by adopting microwave synthesis technology. The configuration is ideal for conventional glassware synthesis, distillation, reflux, addition of reagents during synthesis, and easy sampling.

The Classic Glassware setup allows use of all commonly used laboratory glassware and provides the suitable apparatus for a full reaction optimisation for research or teaching purposes. It allows the chemists to perform synthetic reactions under reflux and any chemical reaction currently carried out with hot plates, heating mantles or oil baths that could be rapidly improved by adopting microwave synthesis technology. The configuration is ideal for conventional glassware synthesis, distillation, reflux, addition of reagents during synthesis, and easy sampling.

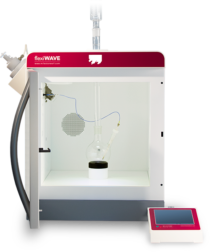

High pressure synthesis

Difficult syntheses are typically carried out in refluxing conditions using high boiling solvents such as xylenes, 1,2-dichlorobenzene and N-methyl pyrrolidone. These are then difficult to remove upon workup, especially as the reaction scale increases. The High-Pressure setup is capable of replacing reflux devices whilst using a solvent of a lower boiling point than previously employed. If required however, high temperature reactions (up to 300 °C) can be performed. The system can use a single high pressure vessel or up to 15 simultaneously for parallel synthesis. Software controlled magnetic stirring is provided in every vessel.

Difficult syntheses are typically carried out in refluxing conditions using high boiling solvents such as xylenes, 1,2-dichlorobenzene and N-methyl pyrrolidone. These are then difficult to remove upon workup, especially as the reaction scale increases. The High-Pressure setup is capable of replacing reflux devices whilst using a solvent of a lower boiling point than previously employed. If required however, high temperature reactions (up to 300 °C) can be performed. The system can use a single high pressure vessel or up to 15 simultaneously for parallel synthesis. Software controlled magnetic stirring is provided in every vessel.

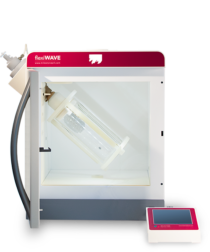

Solid phase synthesis and reactions

Heating heterogeneous reaction mixtures, thick media or solid phase samples suffers from non-homogeneous temperature distribution and stirring difficulties using conventional microwave instruments. The innovative Solid-Phase setup offers the unique capability of rotating the reaction vessel to achieve complete homogenous bulk heating of slurries, viscous and solid reaction mixtures media. The reaction temperature is controlled by a contact-less infrared sensor. The Solid-Phase setup allows synthesis and reactions under normal atmosphere, inert gas, and vacuum. Common applications include functionalisation and modifications of materials, polycondensation, coating, and dehydration of natural oils.

Heating heterogeneous reaction mixtures, thick media or solid phase samples suffers from non-homogeneous temperature distribution and stirring difficulties using conventional microwave instruments. The innovative Solid-Phase setup offers the unique capability of rotating the reaction vessel to achieve complete homogenous bulk heating of slurries, viscous and solid reaction mixtures media. The reaction temperature is controlled by a contact-less infrared sensor. The Solid-Phase setup allows synthesis and reactions under normal atmosphere, inert gas, and vacuum. Common applications include functionalisation and modifications of materials, polycondensation, coating, and dehydration of natural oils.

User interface

The flexiWAVE system is controlled via a compact terminal with an easy-to-read, bright, full-colour, touchscreen display and has multiple USB and Ethernet ports for interfacing to the local laboratory network. The terminal runs a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. Simply recall a previously stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilising a sophisticated PID algorithm. Furthermore, all reaction parameters can be modified ‘on-the-fly’ thus assuring the highest flexibility of operation

The flexiWAVE system is controlled via a compact terminal with an easy-to-read, bright, full-colour, touchscreen display and has multiple USB and Ethernet ports for interfacing to the local laboratory network. The terminal runs a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. Simply recall a previously stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilising a sophisticated PID algorithm. Furthermore, all reaction parameters can be modified ‘on-the-fly’ thus assuring the highest flexibility of operation