Total fat determination in foods and dairy products

The traditional fat extraction methods are very labour intensive and time-consuming. Large amounts of solvents are required to remove fat from the sample matrix, resulting in very high running costs. As an example, conventional fat extraction of pretreated cheese usually requires 3 hours and over 100ml of solvent per sample and is therefore not time – or cost efficient.

Furthermore they expose laboratory technicians to dangerous solvents. To overcome these limitations, Milestone has developed a fast yet accurate microwave-based technology which allows the chemist to carry out the simultaneous total fat determination in foods in just 90 minutes with equivalent results to those obtained with reference methods. The ETHOS X determines total fat as a result of two working steps. In the first step sample hydrolysis and extraction take place simultaneously at relatively low elevated temperature and pressure conditions. In the second step a known aliquot of the solvent with the extracted fat is evaporated allowing the chemist to weigh and measure the fat content.

Furthermore they expose laboratory technicians to dangerous solvents. To overcome these limitations, Milestone has developed a fast yet accurate microwave-based technology which allows the chemist to carry out the simultaneous total fat determination in foods in just 90 minutes with equivalent results to those obtained with reference methods. The ETHOS X determines total fat as a result of two working steps. In the first step sample hydrolysis and extraction take place simultaneously at relatively low elevated temperature and pressure conditions. In the second step a known aliquot of the solvent with the extracted fat is evaporated allowing the chemist to weigh and measure the fat content.

Features

- One method profile for most foods

- Hydrolysis and extraction in one step

- High sample throughput, 12 total fat determinations in 90 minutes

- Large sample amount, up to 10g

- Green method, just 25ml of solvent required

- The fat obtained can be used for fatty acid analysis

- Reproducible and fully documented

- Safe working conditions

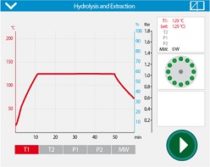

Hydrolysis and extraction

Up to 12 samples can be analysed simultaneously, with a typical sample amount up to 10g. 10ml of diluted acid and 25ml of solvent are used for most matrices. The combined hydrolysis and extraction process takes place at 125°C and requires approximately 50 minutes or less. Temperature is monitored and controlled in each and every vessel by using a unique combination of fibre optic and infrared temperature sensors. The ETHOS X built-in magnetic stirrer assures an even heating and temperature uniformity in all vessels, as well as intensive mixing between the aqueous and the solvent phases.

Up to 12 samples can be analysed simultaneously, with a typical sample amount up to 10g. 10ml of diluted acid and 25ml of solvent are used for most matrices. The combined hydrolysis and extraction process takes place at 125°C and requires approximately 50 minutes or less. Temperature is monitored and controlled in each and every vessel by using a unique combination of fibre optic and infrared temperature sensors. The ETHOS X built-in magnetic stirrer assures an even heating and temperature uniformity in all vessels, as well as intensive mixing between the aqueous and the solvent phases.

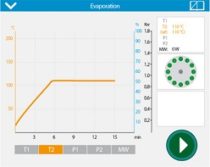

Solvent evaporation

A measured aliquot of the solvent with the extracted fat is evaporated in disposable cups, located in a dedicated rotor, in just 15 minutes. The evaporation process takes place under controlled temperature and vacuum conditions, to avoid the thermal degradation of the fat content. At the completion of the evaporation, the fat content is immediately weighed on a balance that is directly interfaced with the ETHOS X, taking advantage of the extremely short cooling time of the disposable cups. The instrument operating software automatically calculates the fat content and all the statistics associated with the analysis of the 12 samples analysed.

A measured aliquot of the solvent with the extracted fat is evaporated in disposable cups, located in a dedicated rotor, in just 15 minutes. The evaporation process takes place under controlled temperature and vacuum conditions, to avoid the thermal degradation of the fat content. At the completion of the evaporation, the fat content is immediately weighed on a balance that is directly interfaced with the ETHOS X, taking advantage of the extremely short cooling time of the disposable cups. The instrument operating software automatically calculates the fat content and all the statistics associated with the analysis of the 12 samples analysed.

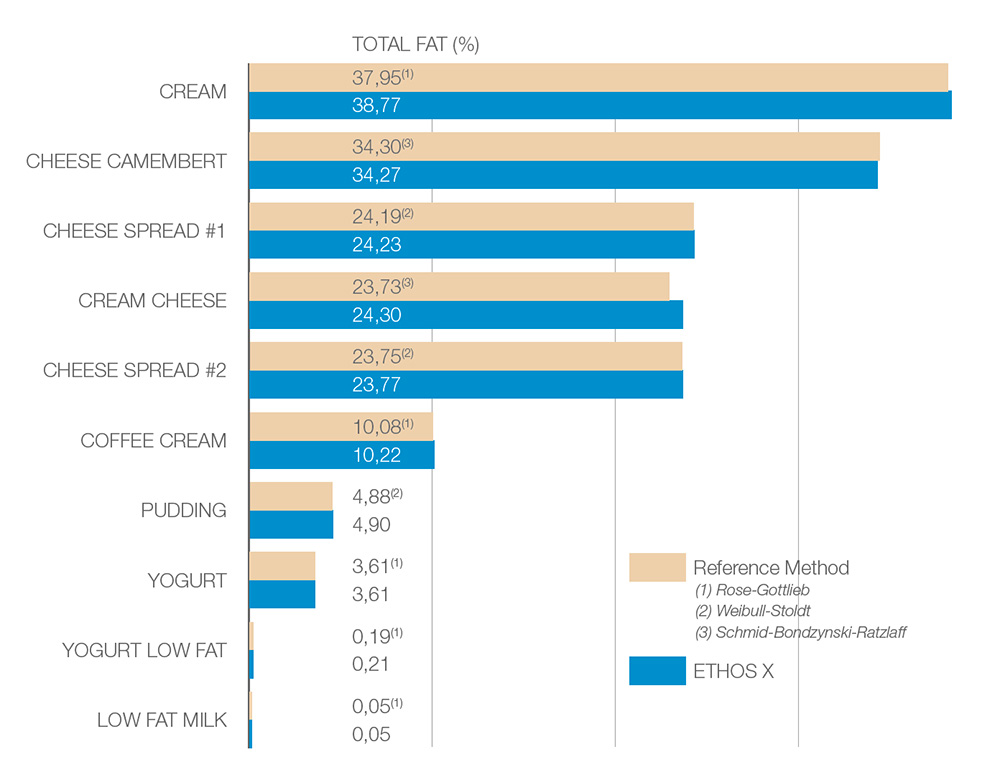

Performance vs traditional methods

User Interface

The ETHOS X is controlled via new compact terminals with an easy-to-read, bright, full-colour, touchscreen display. The terminals run a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. US EPA methods are already preloaded, simply recall a stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilising a sophisticated PID algorithm. There is no need to input the number of samples or weights being extracted, as the software will automatically regulate the microwave power accordingly. This assures a consistent quality of extraction and simplifies the use of the instrument.

The ETHOS X is controlled via new compact terminals with an easy-to-read, bright, full-colour, touchscreen display. The terminals run a completely new user-friendly, icon-driven, multi-language software to provide easy control of the microwave run. US EPA methods are already preloaded, simply recall a stored method or create a new one, press ‘START’ and the system will automatically follow the user defined temperature utilising a sophisticated PID algorithm. There is no need to input the number of samples or weights being extracted, as the software will automatically regulate the microwave power accordingly. This assures a consistent quality of extraction and simplifies the use of the instrument.